Company profile

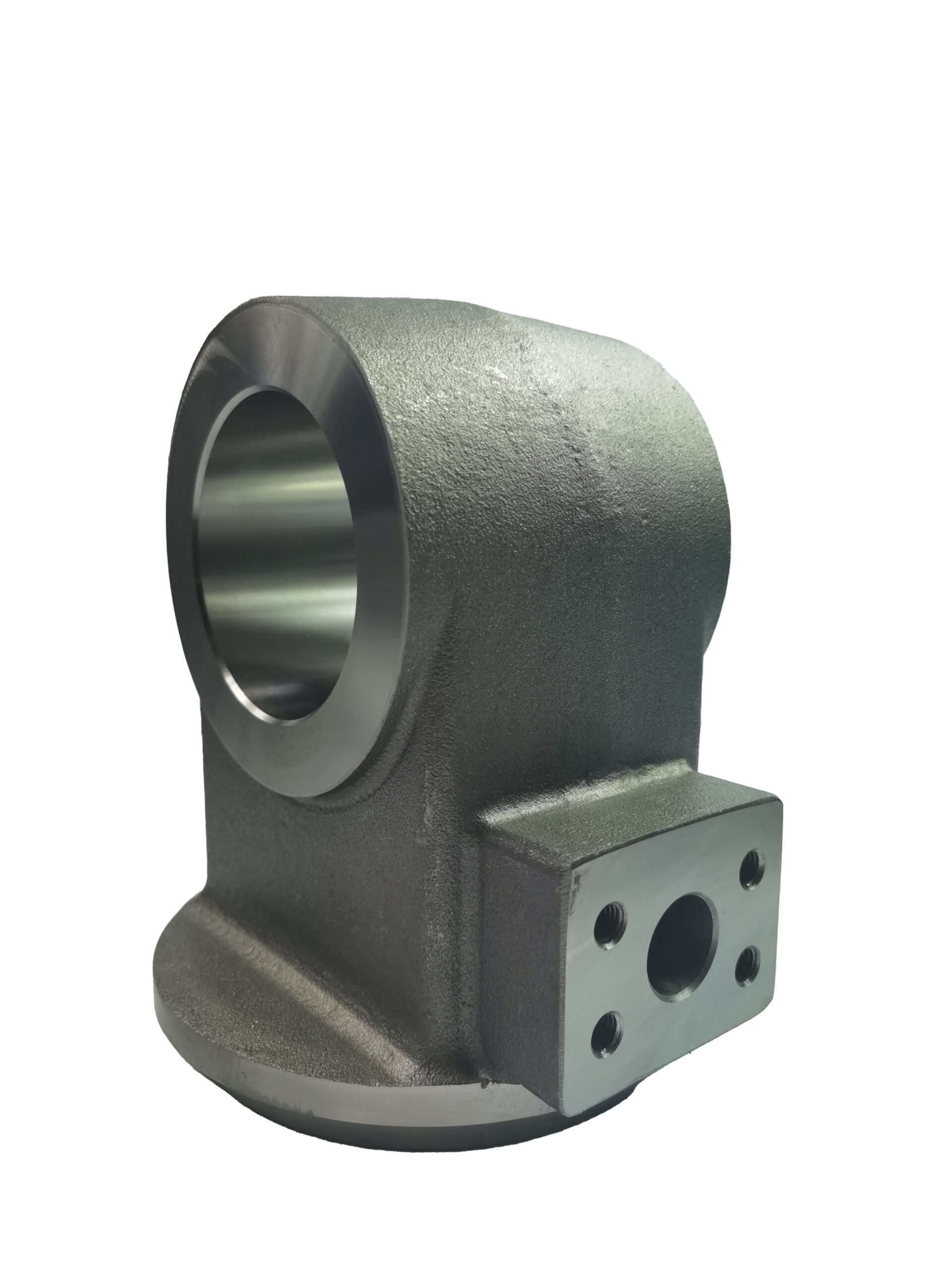

♦♦♦WeForging is a one-stop

manufacturing enterprise specializing in precision forging and precision machining. It also focuses on the supply of high-strength, wear-resistant parts

for agricultural machinery and forestry equipment. We adopt advanced forging technology + flaw detection equipment + material testing and CNC

precision machining to ensure excellent product performance. Widely used in tractors, harvesters, tillage equipment, logging machinery, tree fixtures and other fields.

2. Application of Forgings in agricultural equipment

1. Key tractor parts

WeForging produces high-strength forged components such as:

gears, gear shaft, tooth ring, shaft gear

transmission shafts, wheel shaft

connecting rods, fork, swing arm forging

hydraulic components, piston rod, cylinder bottom, piston, fork lug

These components ensure a consistent and efficient output of the tractor in heavy-duty plowing, seeding, and harvesting operations.

2.Core advantages:

fatigue resistant forging process, good density, uniform structure, greatly extended service life;

precision machining (precision machining) to ensure the matching accuracy between products, reduce friction and reduce life;

customized design (customized solutions), suitable for different parts, tractor brand logo custom manufacturing

3. Harvester and combine parts

Forgings products are also widely used in grain harvesters and forage harvesters, including:

Gear box

Gear box

Driveline component

Flange connector, nut, screw

Machined part

Sprocket wheel

Bend the arm

Bearing block

cutting blades

These components are made of wear-resistant alloy steel, significantly increasing harvesting efficiency and reducing maintenance requirements.

Core advantages:

Core advantages:

optimized cutting performance to reduce crop losses

heat-treated strengthening, impact resistance and wear resistance

One-stop production (modular design) to facilitate the optimization of technology

4. Farming equipment parts

Share (plowshares)

rotary blades

subsoiler shanks

Connecting rod, rod head, lug, fork

Cylinder forging: flange, cylinder head, piston, nut

These components are made of special materials and undergo surface hardening treatment to provide high wear resistance in hard soil conditions and harsh environments.

Core advantages:

Core advantages:

superior wear resistance, reduce replacement frequency

Precision gear forgings: Stable power output

replaceable tip design to save maintenance costs

Application of WeForging in forestry equipment

Logging machine and wood processing equipment parts

We offer loggers, wood chippers, log splitters ** :

Efficient transmission parts

hydraulic cylinders

saw chain guide bars

chipper blades

high-tensile bolts, locking nuts

These parts adopt special alloy steel + forging + high-strength surface treatment to ensure stable operation under high impact and abrasive conditions (abrasive conditions).

Core advantages:

Core advantages:

ultra-high hardness, resistant to wood friction

anti-corrosion coating, suitable for humid environment

Precision machine (dynamic balance design), reduce the wear in the work

5. Forestry tractor and wood grabber parts

WeForging provides for forestry tractors and grapple loaders :

WeForging provides for forestry tractors and grapple loaders :

slewing rings

Hydraulic cylinder components

Steering cylinder component

Grab tooth fittings

drive shafts

Guide wheel

Driving wheel

track links

Non-standard nut customization

These components undergo special heat treatment (carburizing and quenching), which greatly increases the strength, yield strength and tensile strength of the product.

Core advantages:

Core advantages:

extreme condition adaptability (extreme condition adaptability), suitable for rough terrain

Forging-based high-strength design (lightweight yet high-strength) to improve working efficiency

Replaceable accessories (long-life lubrication design) ensure the continuity of production

5. the application of CNC machining in gear manufacturing

(1) Processing method:

CNC milling gear (large module gear ring)

CNC hobbing (small module lot gear)

CNC gear shaper (Internal gear machining)

CNC grinding (high precision hard face gear)

(2) CNC pre-processing of gear forging blank

Turning/milling gear blanks (to ensure datum accuracy)

NC drilling/tapping (machining mounting holes, weight reduction holes)

(3) Gear post-processing and testingQuenching treatment

CNC deburring (improves surface quality)

CNC coordinate measurement (CMM) (detection of tooth profile error, tooth spacing deviation)

6.Why choose WeForging?

✔ 40+ years of forging expertise

✔ ISO 9001 certified quality

✔ full-process quality control from raw materials to finished products

✔ global supply chain support

📩 Contact us for customized agricultural and forestry equipment component solutions!

#AgriculturalParts #ForestryComponents #ForgingExpe #GearForgings #HydraulicCylinder